Antislip Panels

Product Details:

- Composition Polyethylene with anti-slip mineral additives

- Operating Temperature -30C to +80C Celsius (oC)

- Application Industrial flooring, walkways, ramps, loading zones, wet areas

- Usage Industrial

- Material High-Density Polyethylene (HDPE)

- Diameter 3.2 mm Millimeter (mm)

- Size Standard

- Click to View more

X

Antislip Panels Product Specifications

- Industrial

- Polyethylene with anti-slip mineral additives

- 2% - 3%

- High-Density Polyethylene (HDPE)

- Black, Silver, Blue

- 3.2 mm Millimeter (mm)

- Industrial flooring, walkways, ramps, loading zones, wet areas

- Textured Antislip Surface

- Standard

- -30C to +80C Celsius (oC)

- 130C 137C

Product Description

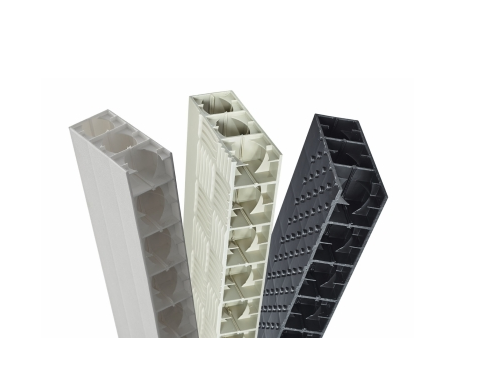

Antislip structure- Five bars

- Studs

- Orange skin

- 50 mm (2")

- Five bars: 3.3 mm (0.13")

- Studs: 3.3 mm (0.13")

- Orange skin: 3.3 mm (0.13")

PP COPO / HDPE

- Internal structure : 50 mm x 50 mm (2x2")

- Standard dimensions :1200 mm x 1000 mm x 50 mm (102.36" x 39.37" x 1.97") (L x W x H)

Weight-Five bars

- PP: 12 kg/m (2.50 lb/ft)

- HDPE*: 13 kg/m (2.70 lb/ft)

- PP: 12 kg/m (2.50 lb/ft)

- HDPE*: 13 kg/m (2.70 lb/ft)

- PP: 11 kg/m (2.30 lb/ft)

- PP 50 mm: R [mK/W] = 0.274

- HDPE 35 mm: R [mK/W] = 0.245

Distance from antiskid profile to edge: 40 mm (1.57")

Orange skin: no outside edge

Double rib

The antislip panels have double rib in the middle (cross). This facilitates production of 40 cm, 50 cm and 60 cm (15.75", 19.69" and 23.62") high panels.

Colours (US:Colors)

- PP prime: UV beige (RAL 7032)

- PP recycled:Black

- PE* prime:UV white (RAL 9010), black

- Other colours (colors) possible on request.

- Paneltim advises against using dark colours (colors) for outside use.

On specific request half panels with antiskid profile can be offered. These open half panels have a thickness of 27 mm (1.06"), a checker plate or studs profile on the one side, and an open rib structure on the other side.

Extensive testing

Both antiskid profiles (checker plate, studs) have been tested for their antiskid properties. Both profiles perform well under these tests, both in wet and in dry condition.

Flexible

The antiskid profiles always have a double rib (cross) in the middle. This facilitates the production of antiskid panels of 40 cm, 50 cm and 60 cm (15.75", 19.69" and 23.62").

No internal accumulation of dirt

The internal cell structure ensures that the panels are always closed all around, even when cutting to size, avoiding ingression of dirt or moisture into the panels.

Processing

- The panel can be processed using regular technic to make plastic constructions: butt welding, extrusion welding or hot air welding. The short welding cycle considerably improves overall processing time.

- The panels being manufactured in prime polypropylene or polyethyleen, joining with solid panels, tubes, etc is possible.

- Structural analysis

- Technical files

- Paneltim strongly recommends avoiding dark colors for outside use.

- Paneltim strongly recommends prime material for structural applications.

- Technical datasheets are only available for panels in prime material.

Superior Safety and Durability

Our antislip panels guarantee reliable traction in high-risk zones, thanks to advanced mineral additives and textures. Designed to perform under harsh conditions, the panels maintain integrity and safety even in wet, oily, or chemically exposed environments. Their robust load-bearing capacity ensures suitability for heavy-duty usage.

Customizable Solutions for Diverse Applications

Choose from multiple thicknesses (5mm, 8mm, or custom), colors (black, yellow, or bespoke hues), and surface patterns to suit your project's exact requirements. Standard panels measure 600mm x 1200mm, but dimensional customization allows adaptation to any layout, making them perfect for industrial, commercial, or public spaces.

Simple Installation and Maintenance

Installation is straightforward with options for bolt-down or adhesive fixing, adapting easily to varied flooring substrates. The low water absorption and high resistance to environmental factors mean minimal upkeep, while their Class B fire rating and excellent UV resistance protect your investment over the long term.

FAQ's of Antislip panels:

Q: How are antislip panels installed?

A: Antislip panels can be secured using either a bolt-down method or adhesive fixed, depending on the substrate and application environment. Both installation approaches provide stable, long-lasting results, with minimal preparation required for most industrial flooring surfaces.Q: What surfaces and environments are suitable for these panels?

A: These panels are ideal for use in industrial flooring, walkways, ramps, loading zones, and wet areas. Their robust environmental resistance to chemicals, oils, moisture, and UV exposure ensures reliable performance in even the most challenging settings.Q: When should custom sizes or colors be considered?

A: Custom sizes or colors may be specified when standard panels do not meet the spatial or aesthetic needs of your application. This can accommodate unusual layouts, match existing color schemes, or comply with safety color-coding requirements.Q: Where are antislip panels most commonly applied?

A: Antislip panels are frequently installed in factories, warehouses, public walkways, ramps, loading docks, and any locations where slip hazards are a concern. Their high load-bearing capacity and slip resistance make them suitable for both pedestrian and vehicular traffic zones.Q: What benefits does the R13 slip resistance rating provide?

A: An R13 slip resistance rating ensures superior traction, reducing the risk of slips and falls-even in the presence of water, oil, or other contaminants. This makes these panels a preferred choice for safety-critical environments.Q: How do these panels support industrial safety?

A: With their fire rating (Class B, EN 13501-1), high load capacity, low water absorption, and robust chemical and oil resistance, antislip panels significantly enhance workplace safety, contributing to compliance with regulations and reducing accident incidence.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sandwich Construction Panels' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |