Lightweight Panels

Product Details:

- Operating Temperature -10C to 60C Celsius (oC)

- Application Wall Cladding, Interior Partitioning, Modular Construction

- Composition Polyurethane, Fibre Cement

- Usage Showrooms / Stores

- Material High-Density Polyurethane Foam Core with Fibre Cement Board Surface

- Size 6"x5ft

- Diameter 25 mm Millimeter (mm)

- Click to View more

Lightweight Panels Product Specifications

- Showrooms / Stores

- Above 120C (Core)

- Protective Layer with Weather Resistant Finish

- White and Black

- 6"x5ft

- Polyurethane, Fibre Cement

- -10C to 60C Celsius (oC)

- High-Density Polyurethane Foam Core with Fibre Cement Board Surface

- 25 mm Millimeter (mm)

- Wall Cladding, Interior Partitioning, Modular Construction

Product Description

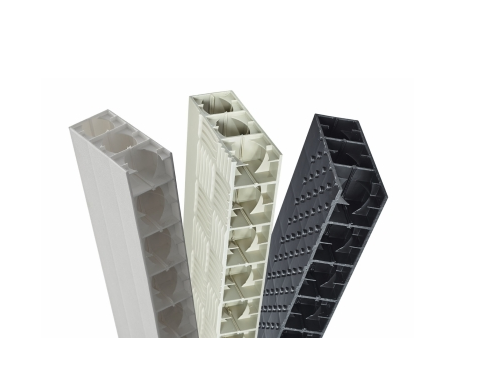

Thickness

- 20 mm (0.8")

- 50 mm (2")

Wall thickness

- 20 mm: 3,5 mm (0.8": 0.14")

- 50 mm: 3,5 mm (2": 0.14")

Material

- PP COPO

- HDPE

Internal structure

- 100 mm x 50 mm (4" x 2")

| Thickness | Length x width |

|---|---|

| 20 mm (0.8") | 1200 x 800 mm (47.24" x 31,50")* 1200 x 1000 mm (47.24" x 39.37")* |

| 50 mm (2") | 1200 x 800 mm (47.24" x 31.50")* 1200 x 1000 mm (47.24" x 39.37")* 2600 x 1000 mm (102.36" x 39.37") |

Weight

| Material | 20 mm (0.8") | 50 mm (2") |

|---|---|---|

| PP | +/- 7,5 kg/m +/- 1.54 lb/ft | +/- 10 kg/m +/- 2.05 lb/ft |

| HDPE | +/- 8 kg/m +/- 1.64 lb/ft | +/- 11 kg/m +/- 2.25 lb/ft |

Isolation value

| Thickness | Material | R [mK/W] |

|---|---|---|

| 20 mm (0.8") | PP | 0.189 |

| 50 mm (2") | PP | 0.242 |

| 50 mm (2") | PE | 0.222 |

Colours (US:Colors)

- PP prime: UV beige (RAL 7032), UV white (RAL 9010)

- PP near to prime: Light grey (RAL 7001), white (RAL 9010), blue (RAL 5002)

- PP recycled: Light green, black

- Other colours (colors) possible on request.

- Paneltim advises against using dark colours (colors) for outside use.

Open half panels

Also the half panels can be offered on demand. These open half panels with a thickenss of 11 or 27 mm (0.43" or 1.06") are smooth and flat on one side and have an open rib structure on the other side.

Flexible

Panels with dimensions 1200 mm x 800 mm (47.24" x 31.50") and 1200 mm x 1000 mm (47.24" x 39.37") always have a double rib (cross) in the middle. This facilitates the production of panels of height 40 cm, 50 cm and 60 cm (15.75", 19.69" and 23.62").

No internal accumulation of dirt

The internal cell structure ensures that the panels are always closed all around, even when cutting to size, avoiding ingression of dirt or moisture into the panels.

Processing

The panel can be processed using regular technic to make plastic constructions: butt welding, extrusion welding or hot air welding. The short welding cycle considerably improves overall processing time.

The panels being manufactured in prime polypropylene or polyethyleen, joining with solid panels, tubes, etc is possible.

Available on request

- Structural analysis

- Technical files

Advice and support

- Paneltim strongly recommends avoiding dark colors for outside use.

- Paneltim strongly recommends prime material for structural applications.

- Technical datasheets are only available for panels in prime material.

Superior Fire Safety and Thermal Performance

These lightweight panels excel in fire safety with a Class A fire rating and are engineered to minimize heat transfer, thanks to a low thermal conductivity of 0.028 W/mK. Whether used for partitioning or external cladding, they provide added security and improved energy efficiency in any construction project.

Exceptional Durability and Weather Resistance

Constructed with a high-density polyurethane core and protected by a fibre cement board surface, these panels offer superior weatherproofing and UV resistance. The protective layer and smooth/matte finish make them suitable for both indoor and outdoor use, ensuring longevity in diverse environments.

Quick and Clean Dry Fix Installation

Designed for dry fixing with a tongue and groove edge profile, the installation process is fast and mess-free. Panels can be easily fitted together, minimizing downtime and reducing labour requirements while maintaining structural integrity and superior sound insulation (up to 35 dB).

FAQ's of Lightweight Panels:

Q: How are lightweight panels installed using the dry fixing method?

A: These panels are designed for dry fixing, which means they can be quickly and cleanly installed without wet adhesives. The tongue and groove edge profile enables straightforward alignment and secure connection between panels, making installation efficient and reducing construction time.Q: What makes these panels beneficial for wall cladding and interior partitioning?

A: Lightweight panels offer high fire resistance (Class A), effective thermal insulation, and sound insulation up to 35 dB, making them ideal for wall cladding and interior partitions. Their smooth/matte finish and weather-resistant coating ensure durability and aesthetic appeal in a variety of applications.Q: When is it recommended to use these panels for modular construction projects?

A: These panels are suited for modular construction whenever fast, clean installation and lightweight material are priorities. Their versatility, compressive strength over 120 kPa, and thermal properties allow use in both temporary and permanent modular structures within operating temperatures of -10C to 60C.Q: Where can these panels be sourced in India for large-scale projects?

A: As a distributor, exporter, manufacturer, supplier, and trader in India, these panels are widely accessible through authorized channels. Service providers can assist with bulk orders and installation services for wall cladding, partitions, and modular builds across the country.Q: What process ensures the panels' weather resistance and long-term durability?

A: Each panel features a protective layer with a weather-resistant finish that shields against moisture, UV rays, and other environmental factors. The fibre cement board surface, combined with high-density polyurethane core, ensures minimal water absorption (<2% by volume) and sustained performance over time.Q: How does the composition of polyurethane and fibre cement enhance the panel's properties?

A: The core material, high-density polyurethane foam, provides excellent thermal insulation and compressive strength, while the fibre cement board surfaces add rigidity, durability, and fire resistance. This composition delivers balanced mechanical and thermal advantages for various construction environments.Q: What are the key benefits of using lightweight panels with high UV resistance and smooth/matte finish?

A: Panels with high UV resistance maintain their colour and structural integrity even in harsh sunlight, making them ideal for exposed outdoor applications. The smooth/matte surface finish contributes to an attractive appearance, easier cleaning, and resistance to wear and weathering.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Sandwich Construction Panels' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese