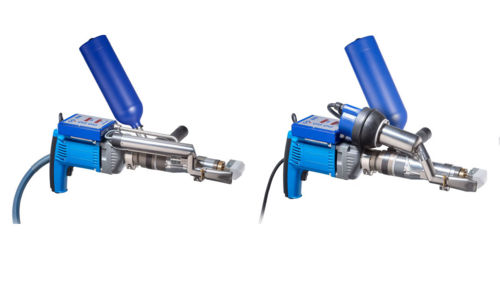

EXWELD sigma3 EC TWISTY

Product Details:

- Operating Voltage 50-90 V

- Operating Temperature 150C - 400C

- Composition Fe, Mn, Si, C

- Application General purpose welding, structural fabrication

- Material Mild Steel

- Diameter 3.15 mm

- Flux Content High (%)

- Click to View more

X

EXWELD sigma3 EC TWISTY Price And Quantity

EXWELD sigma3 EC TWISTY Product Specifications

- 50-90 V

- Mild Steel

- Rutile Cellulosic

- General purpose welding, structural fabrication

- 3.15 mm

- High (%)

- 1450C

- 150C - 400C

- Fe, Mn, Si, C

Product Description

Features:

- WEGENER microprocessor control system for air and extrudate temperature, and to control the motor

- External air supply in the EC version through a WEGENER air heater 2,500 W

- Switch between actual and target value display for air heater and extrudate temperature

- Cold start protection (start-up protection dependent on time and temperature)

- Monitoring of the pre-set target temperature of the extrudate heater with motor-stop function if the deviation is too high

- TWISTY: Turnable welding shoe support for flexible change of the welding direction

- Easily exchangeable PTFE welding shoe, adjustable front handle

- The scope of delivery includes a welding shoe of your choice

Range of Application:

Manufacture of reservoirs, tanks and containers, manufacturer of plastic apparatus, pipeline construction, ventilation, automotive, roofing, landfill technology

Materials:

PE, PP, PVDF and other weldable thermoplastic material

| Technical Data | sigma3 EC TWISTY Item no. 30274 |

|---|---|

| Power supply: | 230 V 1/N/PE 50/60 Hz |

| Power consumption: | 3,690 W |

| Air requirement: | > 300 l/min |

| Heating capacity (air): | 2,500 W |

| Welding capacity (PE): | approx. 1.9 kg/h |

| Welding capacity (PP): | approx. 1.7 kg/h |

| Welding rod diameter: | PE: 3, 4, 5 mm / PP: 3, 4 mm |

| Weight: | 5.4 kg |

| Dimensions (L x H x W in mm): | 440 x 250 x 130 |

Reliable Welding Performance

The EXWELD sigma3 EC TWISTY electrode is engineered to deliver stable arcs and consistent welds regardless of position, offering flexibility for a variety of welding environments. The rutile cellulosic coating not only enhances arc control but also simplifies slag removal, promoting higher work efficiency and clean results.

Optimal Storage and Packaging

To maintain electrode integrity, the product should be stored in a dry ambient environment below 40C. Each batch is packaged in a sealed carton, safeguarding the electrodes from moisture and contamination. This ensures a dependable shelf life of 12 months and performance consistency from box to box.

Versatile Application Scope

Ideal for general purpose welding and structural fabrication work, the EXWELD sigma3 EC TWISTY adapts to diverse operational needs. Its capacity to operate using both AC and DC (recommended DC+) with excellent arc stability provides unparalleled convenience across various fabrication projects and site conditions.

FAQ's of EXWELD sigma3 EC TWISTY:

Q: How should EXWELD sigma3 EC TWISTY electrodes be stored for optimal shelf life?

A: Store the electrodes in a dry, ambient environment with a temperature below 40C. The sealed carton packaging protects against moisture, helping maintain the quality and performance of the electrodes for up to 12 months.Q: What are the recommended current types and polarity for using these electrodes?

A: EXWELD sigma3 EC TWISTY can be used with both AC and DC power sources. For best welding results, DC+ polarity or AC is recommended, ensuring stable arc performance across all welding positions.Q: When is it suitable to use EXWELD sigma3 EC TWISTY electrodes in fabrication projects?

A: These electrodes are ideal for general purpose welding and structural fabrication. They perform efficiently in operating temperatures ranging from 150C to 400C, making them suitable for a broad range of industrial and construction tasks.Q: Where can these electrodes be applied in terms of welding positions?

A: EXWELD sigma3 EC TWISTY is designed for use in all welding positions, providing significant flexibility for welders working on frames, pipelines, or structures requiring varied joint orientations.Q: What is the process for using the electrode to achieve clean welds?

A: To ensure clean results, adjust the operating voltage to 50-90 V and maintain appropriate welding temperature. The high flux content and rutile cellulosic coating help create stable arcs and make slag removal easy after welding.Q: What are the benefits of using this electrode in structural welding?

A: The electrode delivers excellent arc stability, easy slag removal, and adaptability to both AC and DC currents. Its high-quality welds reduce defects and rework, boosting productivity and overall project integrity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Extrusion Welding Machine' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese