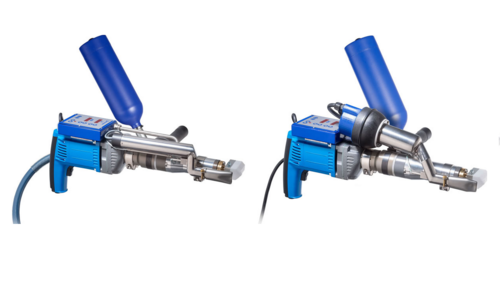

EXWELD Pellet Extrusion Welder

Product Details:

- Operating Voltage 230V AC Volt (V)

- Composition Polyethylene Pellets

- Operating Temperature Up to 300C Celsius (oC)

- Application Plastic welding, Repair of plastic components, Joining HDPE/PVC pipes

- Usage Welding Purpose

- Material High-grade Polyethylene

- Size Standard

- Click to View more

X

EXWELD Pellet Extrusion Welder Product Specifications

- High-grade Polyethylene

- Non-Coated

- 3 mm Millimeter (mm)

- 230V AC Volt (V)

- EXWELD Pellet Extrusion Welder

- 130C - 140C

- Up to 300C Celsius (oC)

- Standard

- Plastic welding, Repair of plastic components, Joining HDPE/PVC pipes

- Polyethylene Pellets

- Welding Purpose

Product Description

Features:

- WEGENER microprocessor control system for air and extrudate temperature, and to control the motor

- Own air supply in the SC version through a WEGENER brushless Airbox 2,200 W

- External air supply in the EC version through a WEGENER air heater 2,500 W

- Switch between actual and target value display for air heater and extrudate temperature

- Cold start protection (start-up protection dependent on time and temperature)

- Monitoring of the pre-set target temperature of the extrudate heater with motor-stop function if the deviation is too high

- Easily exchangeable PTFE welding shoe, adjustable front handle

- The scope of delivery includes a unit stand and a welding shoe of your choice

Range of Application:

Manufacture of reservoirs, tanks and containers, manufacturer of plastic apparatus, pipeline construction, ventilation, automotive, roofing, landfill technology

Materials:

PE, PP, PVDF and other weldable thermoplastic material

| Technical Data | alpha3 SC P Item no. 30286 | alpha3 EC P Item no. 30287 | beta3 SC P Item no. 30288 | beta3 EC P Item no. 30289 | gamma3 EC P Item no. 30290 |

|---|---|---|---|---|---|

| Power supply: | 230 V 1/N/PE 50/60 Hz | 230 V 1/N/PE 50/60 Hz | 230 V 1/N/PE 50/60 Hz | 230 V 1/N/PE 50/60 Hz | 230 V 1/N/PE 50/60 Hz |

| Power consumption: | 3,660 W | 3,960 W | 4,560 W | 5,360 W | 5,760 W |

| Air requirement: | self-contained air supply | >300 l/min | self-contained air supply | >300 l/min | >300 l/min |

| Heating capacity (air): | 2,200 W | 2,500 W | 2,200 W | 3,000 W | 3,000 W |

| Welding capacity (PE): | approx.3 kg/h | approx.3 kg/h | approx. 4.6 kg/h | approx. 4.6 kg/h | approx. 6.2 kg/h |

| Welding capacity (PP): | approx. 3 kg/h | approx. 3 kg/h | approx. 4.3 kg/h | approx. 4.3 kg/h | approx. 5.6 kg/h |

| Welding rod diameter:: | pellet / granulate | pellet / granulate | pellet / granulate | pellet / granulate | pellet / granulate |

| Weight: | 7.3 kg | 6.7 kg | 11.0 kg | 10.3 kg | 10.5 kg |

| Dimensions (L x H x W in mm): | 530 x 550 x 140 | 530 x 550 x 135 | 590 x 670 x 140 | 590 x 670 x 140 | 590 x 670 x 140 |

Advanced Control and Precision

The EXWELD Pellet Extrusion Welder stands out with its digital temperature controller and LED display, allowing users to fine-tune operating conditions for diverse applications. Its adjustable extrusion output and variable feed rate help achieve consistent and reliable welds, essential for precision in plastic fabrication and repairs.

Ergonomic and Efficient Design

Weighing only 14.5 kg and featuring an insulated, ergonomic handle, the welder is designed for ease of use during prolonged work sessions. The 3-meter cable enables operators to maneuver the tool conveniently in various environments, ensuring flexibility without compromising safety or efficiency.

Versatile Welding Applications

Engineered for handling high-grade polyethylene pellets, the EXWELD welder is ideal for repairing plastic components, as well as joining HDPE and PVC pipes. Its high heating capacity and wide operating temperature range make it suitable for a broad spectrum of plastic welding tasks, from maintenance to new installations.

FAQ's of EXWELD Pellet Extrusion Welder:

Q: How does the EXWELD Pellet Extrusion Welder operate for plastic welding tasks?

A: The EXWELD Pellet Extrusion Welder uses high-grade polyethylene pellets, which are fed through the machine at variable rates and melted using a 1.5 kW heating system. The molten material is then extruded and used to weld or repair plastic components-ideal for applications like joining HDPE or PVC pipes.Q: What materials can be joined or repaired using this welder?

A: This welder is specifically designed for use with high-grade polyethylene pellets, making it suitable for welding and repairing components made from HDPE and PVC. It is commonly employed in joining pipes and restoring various plastic parts.Q: When is it beneficial to use an extrusion welder instead of traditional welding methods?

A: An extrusion welder is especially beneficial when working with thicker plastic sections, making long seams, or when precise control over weld material is essential. It delivers consistent results, making it ideal for industrial applications or demanding repair projects.Q: Where can this machine be used effectively?

A: The machine can be used anywhere professional plastic welding or repairs are needed-such as construction sites, manufacturing plants, workshops, or for on-field pipe joining. Its portability and three-meter cable provide flexibility for indoor and outdoor use.Q: What is the process for adjusting the feed rate and extrusion output?

A: Both the feed rate and extrusion output are adjustable using the control panel on the welder. The digital controller and LED display allow users to set the desired parameters, ensuring optimal melting and extrusion according to specific project requirements.Q: How does the ergonomic design of the welder benefit operators?

A: The welder features an insulated, ergonomic handle that minimizes fatigue during extended use. Its lightweight construction (14.5 kg) and long cable further enhance maneuverability, allowing users to work safely and efficiently in a range of positions and locations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Extrusion Welding Machine' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese