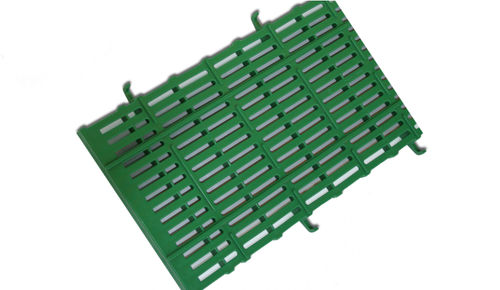

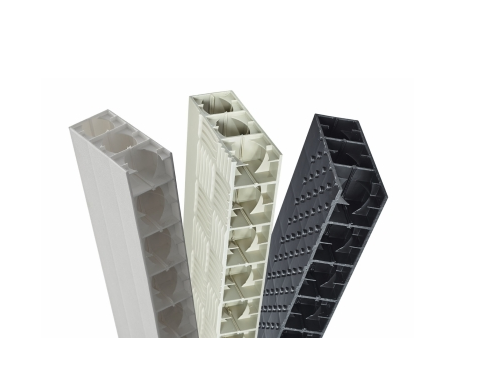

Delta Senior Slats

Product Details:

- Operating Temperature Up to 650C Celsius (oC)

- Composition Copper with flux core

- Application Brazing and Welding Applications

- Usage Industrial

- Material Copper

- Size Standard

- Diameter 3.2 mm Millimeter (mm)

- Click to View more

X

Delta Senior Slats Product Specifications

- Industrial

- Copper with flux core

- 2% - 3%

- Brazing and Welding Applications

- Black, Silver, Blue

- Tin Coated

- 650C

- Standard

- Copper

- 3.2 mm Millimeter (mm)

- Up to 650C Celsius (oC)

Product Description

Slip resistant

- Panltim slats are slip resistant, without sharp elements, providing good grip.

Optimal hygiene

- Paneltim slats provide good overall hygiene thanks to their rounded shape and high throughput. The slats are easy and fast to clean.

Easy installation

- Paneltim slats are easy to install with an easy self-anchoring system.

Fast mounting

- Thanks to a smart self-anchoring system in longitudinal and transversal direction the slats are quick to mount.

Durable

- Panltim slats are slip resistant, without sharp elements, providing good grip.

Ecological

- Paneltim slats are 100% recyclable and keep their raw material value. The slats are free of toxic substances and are compliant to EU regulation 2011/65/EU. When renovating the slats can be reused

Material

- PP COPO

Height

- 25 mm (0.98")

Dimensions

Slats

- 1200 x 400 mm (47.24" x 15.75")

- 1500 x 400 mm (59.06" x 15.75")

- 1600 x 400 mm (62.99" x 15.75")

Height

Weight

- 12,25 kg/m (2.51 lb/ft)

Color (US:Colors)

- Green

Antiskid

- Paneltim Delta senior slats have a functional antiskid profile, without sharp elements..

Durable

- Paneltim Plus open slats are resistant against almost all chemical substances. Thanks to their rigidity they are very resistant to dynamic shocks.

No corrosion

- Paneltim Plus open slats are corrosion free.

Fast installation

- Thanks to a smart self-anchoring system in longitudinal and transversal direction the slats can be fast and easily.

Reliable Performance for Brazing & Welding

Delta Senior Slats offer consistent quality due to their precise copper composition and integrated flux core. The tin coating ensures smooth application and high conductivity, making them an indispensable component in industrial joining processes. Withstanding operating temperatures up to 650C, they guarantee robust bonds in both brazing and welding tasks.

Packaging and Storage Solutions

Packaged securely in boxes, Delta Senior Slats retain their bright, shiny appearance and flux efficacy for up to 24 months. To maximize shelf life, users must store these rods in dry, cool places, protecting the flux and coating from environmental degradation and ensuring optimal performance when needed.

FAQ's of Delta Senior Slats:

Q: How should Delta Senior Slats be stored to ensure maximum shelf life?

A: Delta Senior Slats should be stored in a dry and cool place, protected from moisture and heat. Proper storage maintains their appearance and preserves the flux content, giving them a shelf life of up to 24 months.Q: What is the main benefit of the tin coating on the copper slats?

A: The tin coating enhances their ability to form strong, conductive bonds during brazing and welding by preventing oxidation and ensuring smooth melting and application at high temperatures.Q: When is it recommended to use Delta Senior Slats?

A: These slats are ideal for use in brazing and welding operations that require reliable joint integrity and efficient performance, especially when a bright, shiny appearance is preferred and temperatures may reach up to 650C.Q: Where are Delta Senior Slats manufactured and available for distribution?

A: Delta Senior Slats are manufactured in India and supplied by various distributors, exporters, manufacturers, service providers, suppliers, and traders across the region.Q: What process do the slats support and what is their typical usage?

A: Delta Senior Slats support brazing and welding processes, commonly used for joining metals in fabrication, repair, and installation projects, leveraging their copper composition and integrated flux core for strong results.Q: How does the flux content benefit the brazing and welding application?

A: The 2%-3% flux content aids in cleaning metal surfaces and eliminating oxidation during heating, resulting in secure bonds and preventing defects in the final joint.Q: What is the minimum order quantity for Delta Senior Slats?

A: The minimum order quantity is 50 kg, making them suitable for both small-scale and large industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sandwich Construction Panels' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese