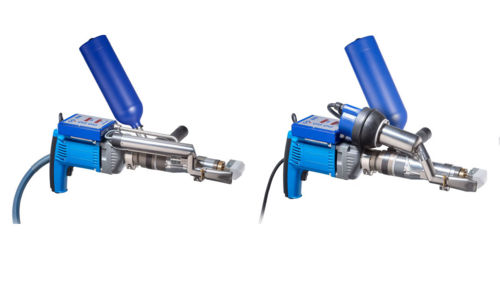

EXWELD beta3 SC

Product Details:

- Operating Voltage 22V 28V

- Application Structural Steel Fabrication, Maintenance, and Repair

- Composition Carbon Steel, Alloying elements

- Operating Temperature Up to 400C

- Material Steel Core

- Diameter 3.2 mm

- Flux Content Self-shielded Flux Core

- Click to View more

X

EXWELD beta3 SC Price And Quantity

EXWELD beta3 SC Product Specifications

- 1400C 1500C

- Up to 400C

- Steel Core

- 3.2 mm

- Special Anti-Moisture Coating

- Carbon Steel, Alloying elements

- Structural Steel Fabrication, Maintenance, and Repair

- Self-shielded Flux Core

- 22V 28V

Product Description

Features:

- WWEGENER microprocessor control system for air and extrudate temperature, and to control the motor

- Own air supply in the SC version through a WEGENER brushless Airbox 2,200 W

- Switch between actual and target value display for air heater and extrudate temperature

- Cold start protection (start-up protection dependent on time and temperature)

- Monitoring of the pre-set target temperature of the extrudate heater with motor-stop function if the deviation is too high

- Easily exchangeable PTFE welding shoe, adjustable front handle

- The scope of delivery includes a unit stand and a welding shoe of your choice

Range of Application:

Manufacture of reservoirs, tanks and containers, manufacturer of plastic apparatus, pipeline construction, ventilation, automotive, roofing, landfill technology

Materials:

PE, PP, PVDF and other weldable thermoplastic material

| Technical Data | beta3 SC Item no. 30279 |

|---|---|

| Power supply: | 230 V 1/N/PE 50/60 Hz |

| Power consumption: | 4,560 W |

| Air requirement: | self-contained air supply |

| Heating capacity (air): | 2,200 W |

| Welding capacity (PE): | approx. 4.6 kg/h |

| Welding capacity (PP): | approx. 4.3 kg/h |

| Welding rod diameter:: | PE / PP: 3, 4, 5 mm |

| Weight: | 10.6 kg |

| Dimensions (L x H x W in mm): | 590 x 390 x 140 |

Versatile All-Position Welding Solution

EXWELD beta3 SC is engineered to accommodate every major welding position-flat, vertical, and overhead-making it an excellent choice for a wide range of structural steel projects. Its compatibility with multiple welding settings enables fabricators and repair teams to complete jobs efficiently and reliably, regardless of the workspace orientation.

Enhanced Durability and Storage Convenience

The vacuum-packed cartons and specialized anti-moisture coating safeguard the electrodes from environmental humidity, extending their shelf life up to 24 months. Proper storage in dry and cool places furthers the longevity and quality of the product, ensuring you use electrodes that maintain peak performance every time.

FAQ's of EXWELD beta3 SC:

Q: How should EXWELD beta3 SC electrodes be stored for optimal performance?

A: To maintain their effectiveness, store EXWELD beta3 SC electrodes in a dry, cool place within their original vacuum-packed cartons. This prevents moisture absorption, thanks to the special anti-moisture coating, and helps preserve their 24-month shelf life.Q: What are the ideal applications for EXWELD beta3 SC?

A: EXWELD beta3 SC is designed for structural steel fabrication, general maintenance, and repair jobs. Its self-shielded flux core makes it suitable for both indoor and outdoor projects where consistent weld quality and low spatter are essential.Q: When can I use EXWELD beta3 SC in terms of welding positions?

A: This electrode is suitable for all welding positions-including flat, vertical, and overhead-providing flexibility and convenience for complex assembly or repairs.Q: Where is EXWELD beta3 SC commonly distributed and supplied?

A: EXWELD beta3 SC is widely available throughout India and is distributed, exported, and supplied by a network of manufacturers, service providers, suppliers, and traders.Q: What is the process for welding with EXWELD beta3 SC?

A: Welding with EXWELD beta3 SC involves using a compatible welding machine set to DCEN (Direct Current Electrode Negative) polarity, with an operating voltage between 22V and 28V. Medium heat input is recommended, and the electrode's flux core automatically produces shielding gases, eliminating the need for external shielding.Q: How does the special anti-moisture coating benefit the user?

A: The unique anti-moisture coating helps prevent the absorption of humidity, which enhances storage life and ensures reliable, high-quality welds-even in challenging environments.Q: What advantages does EXWELD beta3 SC offer during welding?

A: With excellent arc stability, minimal spatter, and the ability to perform in all positions, EXWELD beta3 SC streamlines the welding process and minimizes post-weld cleanup, improving productivity for structural steel and maintenance tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Extrusion Welding Machine' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese