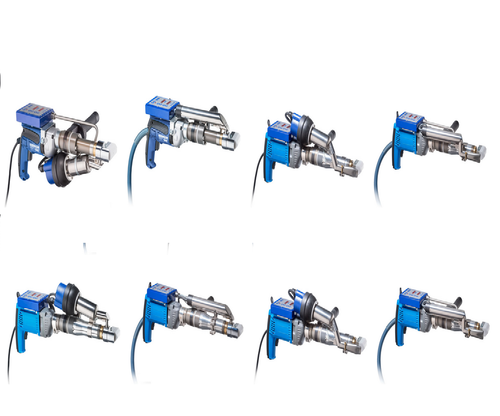

Extrusion Gun

Product Details:

- Application Plastic Extrusion, Hot Air Welding, Fabrication

- Composition Aluminium with precision steel/ceramic nozzles

- Operating Voltage 230 V Volt (V)

- Operating Temperature Up to 550C Celsius (oC)

- Usage Extrusion Gun

- Material Aluminium Alloy

- Size Standard

- Click to View more

X

Extrusion Gun Product Specifications

- Plastic Extrusion, Hot Air Welding, Fabrication

- 230 V Volt (V)

- Aluminium with precision steel/ceramic nozzles

- Aluminium Alloy

- Extrusion Gun

- Standard

- Extrusion Gun

- 32 mm Millimeter (mm)

- Up to 550C Celsius (oC)

- Anodized

- 660C (Aluminium)

Product Description

EXWELD sigma3 SC TWISTYTWISTY: Turnable welding shoe support for flexible change of the welding direction

Welding capacity (PE):approx. 1.9 kg/h

Welding capacity (PP):approx. 1.8 kg/h

TWISTY: Turnable welding shoe support for flexible change of the welding direction

Welding capacity (PE):approx. 1.9 kg/h

Welding capacity (PP):approx. 1.7 kg/h

Welding capacity (PE):approx. 2.6 kg/h

Welding capacity (PP):approx. 2.2 kg/h

Welding capacity (PE):approx. 2.6 kg/h

Welding capacity (PP):approx. 2.2 kg/h

TWISTY: Turnable welding shoe support for flexible change of the welding direction

Welding capacity (PE):approx. 2.6 kg/h

Welding capacity (PP):approx. 2.2 kg/h

TWISTY: Turnable welding shoe support for flexible change of the welding direction

Welding capacity (PE):approx. 2.6 kg/h

Welding capacity (PP):approx. 2.2 kg/h

Welding capacity (PE):approx. 2.4 kg/h

Welding capacity (PP):approx. 1.7 kg/h

Welding capacity (PVC):approx. 2.8 kg/h

Welding rod diameter:PE / PP: 3, 4, 5 mm / PVC 3, 4 mm

Welding capacity (PP):approx. 4.6 kg/h

Welding capacity (PVC):approx. 4.3 kg/h

Welding rod diameter:PE / PP: 3, 4, 5 mm

Welding capacity (PP):approx. 4.6 kg/h

Welding capacity (PVC):approx. 4.3 kg/h

Welding rod diameter:PE / PP: 3, 4, 5 mm

Welding capacity (PP):approx. 4.6 kg/h

Welding capacity (PVC):approx. 4.3 kg/h

TWISTY: Turnable welding shoe support for flexible change of the welding direction

Welding capacity (PE): approx. 4.6 kg/h

Welding capacity (PP):approx. 4.3 kg/h

TWISTY: Turnable welding shoe support for flexible change of the welding direction

Welding capacity (PE): approx. 4.6 kg/h

Welding capacity (PP):approx. 4.3 kg/h

EXWELD Pellet Extrusion Welder

Welding rod diameter: pellet / granulate

Welding capacity (PP):approx.3 kg/h

Welding capacity (PE): approx. 3 kg/h

Welding rod diameter: PE / PP: 3, 4, 5 mm

Welding capacity (PE):approx. 6.2 kg/h

Welding capacity (PP): approx. 5.6 kg/h

Welding rod diameter: PE / PP: 3, 4, 5 mm

Welding capacity (PE): approx. 4.8 kg/h

Welding capacity (PP):approx. 4.3 kg/h

Welding rod diameter: PE: 4 mm

Welding capacity (PE): approx. 0.7 kg/h

Welding rod diameter: PE, PP: 3.4 mm

Welding capacity (PE): approx. 2.6 kg/h

Welding capacity (PP):approx. 2.2 kg/h

Welding rod diameter:PE, PP: 3.4 mm

Welding capacity (PE): approx. 2.6 kg/h

Welding capacity (PP):approx. 2.2 kg/h

On-site blower for extrusion welders with external air supply

Precision and Efficiency Combined

Engineered for demanding plastic extrusion and hot air welding applications, the Extrusion Gun merges advanced power, versatility, and user-focused design. Its corrosion-resistant aluminium alloy construction ensures longevity, while adjustable flow and electronic temperature control offer consistent results. This tool is ideal for everyday fabrication and professional use.

Comfortable and Safe Operation

With an ergonomic, heat-resistant handle and streamlined 2.1 kg build, the Extrusion Gun prioritizes operator comfort during extended tasks. The 3-metre cable grants flexibility, and the anodized coating provides extra corrosion protection. Its safety features and sturdy design ensure a dependable working environment.

FAQ's of Extrusion Gun:

Q: How does the electronic temperature control benefit the extrusion process?

A: The electronic temperature control allows precise adjustment of the working temperature up to 550C, ensuring optimal melting and flow for various plastic extrusion and welding tasks. This improves quality and reduces the risk of material overheating or underheating.Q: What types of applications can this extrusion gun handle?

A: Designed for versatility, the extrusion gun is suitable for plastic extrusion, hot air welding, and general fabrication tasks. It is widely used in construction, repair, and industrial material processing environments.Q: When should I use each nozzle size included with the gun?

A: Different nozzle sizes serve specific purposes: smaller nozzles offer concentrated flow for detail work, while larger ones support higher-volume tasks. The set includes standard sizes to ensure suitability for a range of applications and materials.Q: Where can the Extrusion Gun be optimally utilized?

A: This extrusion gun is ideal for job sites, workshops, and industrial settings across India. Its durable construction and adaptability make it suitable for use in demanding indoor or outdoor conditions.Q: What is the process for adjusting the flow rate?

A: The tool offers an adjustable flow rate up to 240 l/min using its integrated controls. This enables users to fine-tune airflow to match the requirements of specific materials or projects, ensuring consistent and high-quality results.Q: How does the ergonomic heat-resistant handle improve usage?

A: The handle is designed for comfortable gripping and heat resistance, which allows extended operation periods without discomfort. This design reduces strain and enhances control during critical welding and extrusion tasks.Q: What are the main benefits of the aluminium alloy and anodized finish?

A: The aluminium alloy provides a lightweight yet robust body, while the anodized finish enhances corrosion and wear resistance. Combined, these attributes ensure prolonged product life and maintain tool integrity in demanding environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Extrusion Welding Machine' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |