SM x60 UHMWPE

Product Details:

- Output Current 160 Amp

- Frequency 50/60 Hz

- Condition New

- Type Welding Machine

- Power 3700 Watt

- Weight 7.5 Kg

- Input Current 17 A

- Click to View more

X

SM x60 UHMWPE Product Specifications

- Industrial

- Manual

- F

- 17 A

- 2.5-4 mm

- 160 Amp

- 50 Hz

- 7.5 Kg

- 3700 Watt

- Fan Cooling

- Welding Machine

- UHMWPE

- New

- 85%

- 50/60 Hz

- AC

- 450 Sq mm

- 220 Volt

- 160 Amp

- 380 x 130 x 245 mm

SM x60 UHMWPE Trade Information

- All India

Product Description

Features:

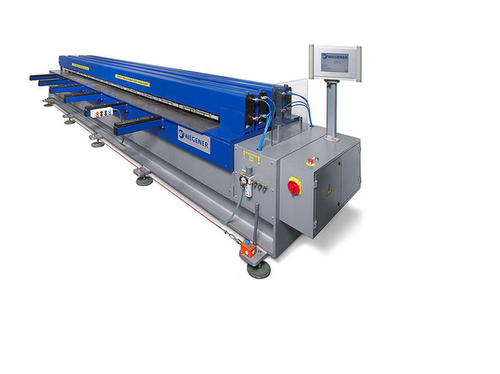

- Solid machine base as a steel structure with integrated precision working tables in a sandwich design that are adapted to the loads

- VARIO-clamping system 2. generation for adjusting the distance between the clamping plate and the edge of the table

- Patented mechanical synchronisation of the working tables; a novelty to achieve a homogeneous application of pressure in the weld seam area

- Process forces regulated via proportional valve

- force-sensing system (incl. compensation of the tractive and frictional forces incl. position transducer) optional

- Siemens S7-1500 with 12" Simatic-Touchscreen

- Material property data record (parameter) with automatic choice of specific welding pressures, temperature and times

- Clamping force increased by a second pair of clamping beams

- Processing of PE 500 and PE 1000

- Special welding lengths uo to 6 m

Range of Application: Manufacture of reservoirs, tanks and containers, manufacture of plastic apparatus, pipeline construction, ventilation systems, serial welding, water treatment systems, scrubbers, environmental technology, swimming pools, transport and logistics.

| Technical Data | SM 360 UHMWPE |

SM 460 UHMWPE |

SM 560 UHMWPE |

|---|---|---|---|

| Machine Length (mm): | 4,700 | 5,700 | 6,700 |

| Machine Width (mm): | 1,350 | 1,350 | 1,350 |

| Machine Height (mm): | 1,400 | 1,400 | 1,400 |

| Total Weight approx. (kg): | 5,800 | 7,500 | 9,000 |

| max. Working Width (mm) | 3,050 | 4,050 | 5,100 |

| Sheet Thickness to be welded (mm): | |||

| PE [0.15 N/mm | 3 to 30 | 3 to 30 | 3 to 30 |

| PP [0.10 N/mm | 3 to 30 | 3 to 30 | 3 to 30 |

| PVDF [0.10 N/mm | 3 to 30 | 3 to 30 | 3 to 30 |

| PVC-C at 8 bar [0.50 N/mm | 3 to 30 | 3 to 30 | 3 to 30 |

| PVC-C at 10 bar [0.50 N/mm | 3 to 30 | 3 to 30 | 3 to 30 |

| PVC-U at 8 bar [0.60 N/mm | 3 to 30 | 3 to 30 | 3 to 30 |

| PVC-U at 10 bar [0.60 N/mm | 3 to 30 | 3 to 30 | 3 to 30 |

| PE 500 | 3 to 25 (1 N/mm) | 3 to 25 (1 N/mm) | 3 to 25 (1 N/mm) |

| PE 1000 | 3 to 12.5 (2 N/mm) | 3 to 12.5 (2 N/mm) | 3 to 12.5 (2 N/mm) |

| Power Supply Standard: | 230/400V 3/N/PE 50/60 Hz | 230/400V 3/N/PE 50/60 Hz | 230/400V 3/N/PE 50/60 Hz |

| Power consumption standard (kW): | 3.5 | 4.5 | 5.5 |

| Compressed air connection (bar): | 10 | 10 | 10 |

| Clamping Force at 8.0 bar (kN): | |||

| Clamping Force at 10 bar (kN): | 150 | 200 | 250 |

| Welding Force: | |||

| Table Force min. (N): | 3,500 | 3,500 | 3,500 |

| Table Force max. at 10.0 bar (kN): | 78 | 104 | 129 |

| Heating Element (B x H in mm) Teflon coated, Tmax = 260 C: | 20 x 50 mm | 20 x 50 mm | 20 x 50 mm |

Reliable Industrial Performance

Engineered for professional environments, the SM x60 UHMWPE Welding Machine delivers consistent and efficient results. Its high output and adjustable settings cater to diverse industrial welding requirements, ensuring durability and safety with its IP21S protection class. The machines robust construction and effective cooling mechanism support intensive operations.

User-Friendly Digital Interface

Featuring a clear digital display, users benefit from precise control and real-time monitoring during welding tasks. This intuitive interface allows operators to easily adjust the arc current, pulse frequency, and other essential parameters, enhancing both accuracy and productivity for manual welding applications.

Optimized for Efficiency and Safety

With an impressive efficiency rate of 85% and built-in fan cooling, the SM x60 ensures stable operation even during extended use. Its insulation grade F and IP21S protection class safeguard against heat and electrical risks. Designed for reliability, it provides peace of mind for industrial welders working in various sectors.

FAQs of SM x60 UHMWPE:

Q: How does the SM x60 UHMWPE Welding Machine accommodate different welding needs?

A: The welding machine supports a wide arc current range up to 160 Amp and accepts rod diameters from 2.5 mm to 4 mm, making it suitable for various industrial applications and welding thicknesses. Its versatile settings enable adjustments for diverse welding requirements.Q: What safety features are integrated in the SM x60 UHMWPE Welding Machine?

A: Safety is ensured with an IP21S protection class, insulation grade F, and fan cooling which collectively reduce electrical and thermal risks during prolonged use. These features protect both the operator and the device in demanding industrial environments.Q: When should I use this welding machine for optimal performance?

A: For best results, operate the machine within its specified duty cycle of 60% to prevent overheating. Ensure youre using compatible rods and appropriate settings based on material thickness and desired weld quality for maximized efficiency.Q: Where can the SM x60 UHMWPE Welding Machine be utilized?

A: Primarily intended for industrial environments, the machine is ideal for manufacturing sites, repair workshops, and fabrication facilities across India. Its portability and robust design suit various on-site welding applications.Q: What is the process for operating this welding machine?

A: The operator connects the machine using the provided 1.8-meter cable, sets desired welding parameters on the digital display, confirms safety measures, and manually controls the welding operation, ensuring a stable arc and effective cooling throughout.Q: How does using the SM x60 UHMWPE benefit industrial welders?

A: With efficient energy use (power factor 0.93, efficiency 85%), digital controls, and reliable safety features, this welding machine enhances productivity, delivers precise welds, and provides long-term durability for professional users in demanding contexts.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PLASTIC SHEET WELDING MACHINE' category

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese