Showroom

Welding Guns are featured with adjustable temperature settings for required melting points. These are handy and can be easily used. Our offered products are used for diverse welding applications.

Extrusion Welding Machine is ideal for the fabrication of plastic materials as well as civil engineering works. It has a compact size which makes the application more convenient and quick.

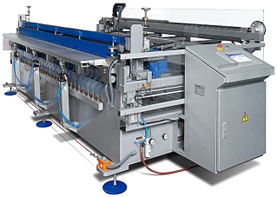

Plastic Sheet Butt Welding Machine is widely used for processing bends, tees and crosses. It is usually found in workshops and industries. This machine has a robust construction and easy installation.

Plastic Sheet Bending Machine is appreciated for its high speed, high performance efficiency, simple features and longer service life. It is easy to use and ensures noiseless operation.

These Bead Removal Tools are made of premium materials and are designed to last, providing durability and endurance. Our tools are the ideal partners to heighten your creativity and open up limitless possibilities in your creative projects, whether you are an expert jeweler or a devoted hobbyist.

Electrical Testers are extensively used for detecting pinholes. These are attributed with high quality, longer functional life, simple features, seamless finishing, reliability and high performance efficiency.

Plastic Pipe Saws are most commonly found in wood working as well as furniture manufacturing industries. These are praised for their low noise application, sturdy construction and high efficiency.

Heating Tools are designed for construction sites and automobile workshops. These are featured with good grip which makes it convenient for the user to use them. Our offered products are compact in size and light in weight.

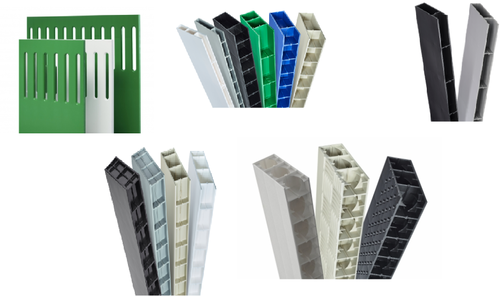

Plastic Pipe Cutting Machines are highly durable, easy to use and sturdy in construction. These are used for cutting pipes made up of plastic material. The said machines can be availed in different specifications.

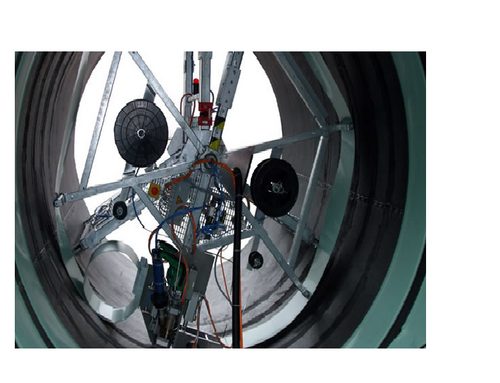

As the name suggests, these WIDOS Pipe Welding Machines ( Butt & Socket Joint ) are widely used for welding pipes in various industries. These are used in industrial and engineering sectors.

|

NAY ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese